Success Stories

Equipment Networking Project

Client: High-strength fastener group

Challenge: Multiple types of equipment with different industrial control systems, lack of unified equipment networking standards; key equipment status relies on manual inspection, failure detection lags; equipment maintenance is mainly 'post-maintenance', unexpected downtime causes production losses.

Solution: Mesflow adopted a three-layer architecture of 'edge gateway + unified protocol + cloud analysis' to deploy an equipment networking platform for the client. Through edge gateways to achieve on-site data collection and preprocessing, through protocol conversion engine to unify heterogeneous protocols, and build equipment digital twin models in the cloud to achieve real-time monitoring, fault early warning, predictive maintenance and other functions.

Results: Significant improvement in Overall Equipment Efficiency (OEE); substantial reduction in unplanned downtime; obvious reduction in equipment maintenance costs; shortened equipment fault response time.

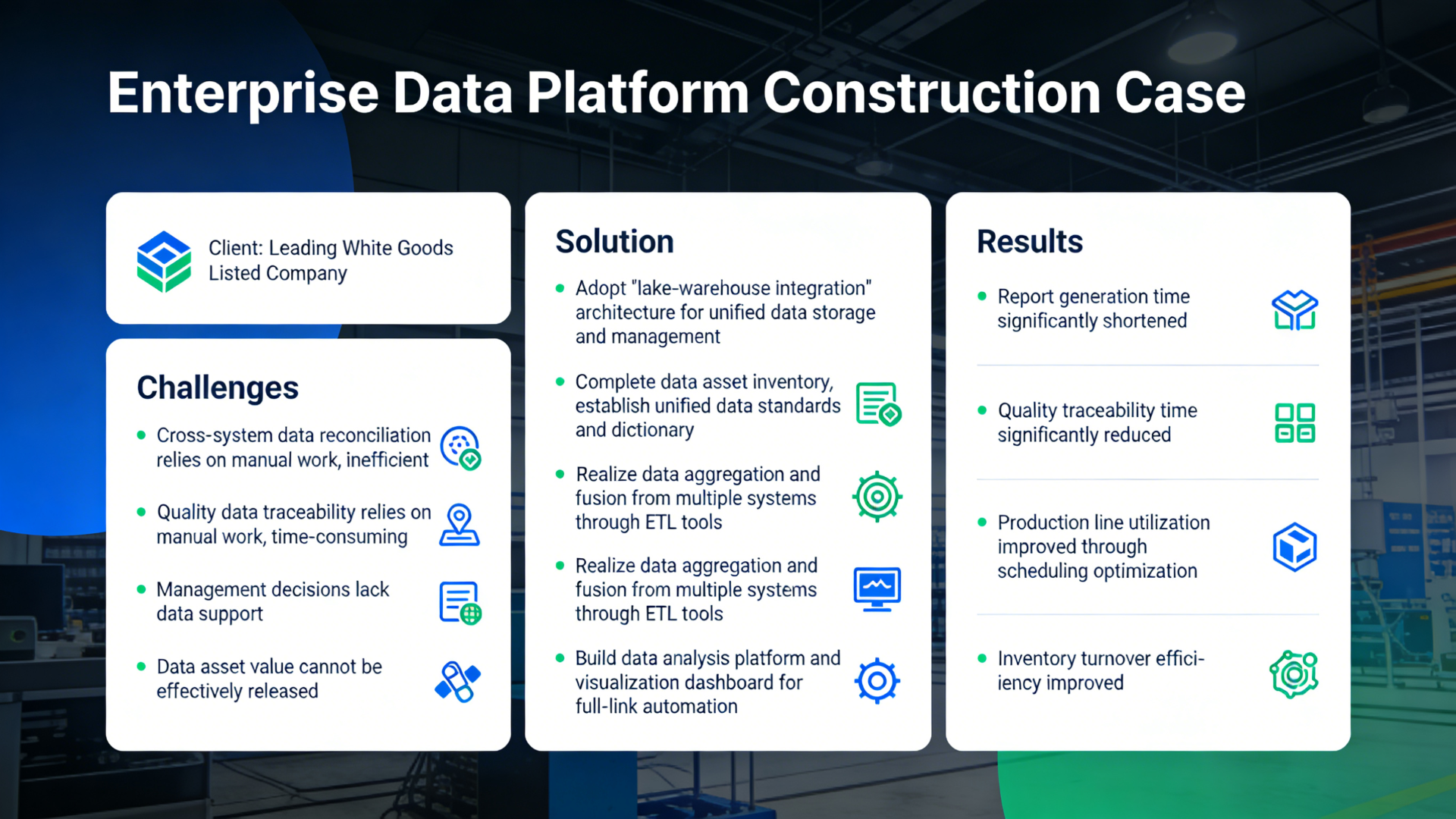

Data Platform Construction

Client: Leading white goods listed company

Challenge: Cross-system data reconciliation relies on manual work, inefficient; quality data traceability relies on manual work, time-consuming; management decisions lack data support; data asset value cannot be effectively released.

Solution: Mesflow built an enterprise-level data platform for the client, adopting a 'lake-warehouse integration' architecture to achieve unified storage and management of global data. Completed data asset inventory, established unified data standards and data dictionary; realized data aggregation and fusion from multiple systems through ETL tools; built data analysis platform and visualization dashboard, realizing full-link automation of data collection, cleaning, analysis, and display.

Results: Report generation time significantly shortened; quality traceability time significantly reduced; production line utilization improved through scheduling optimization; inventory turnover efficiency improved.

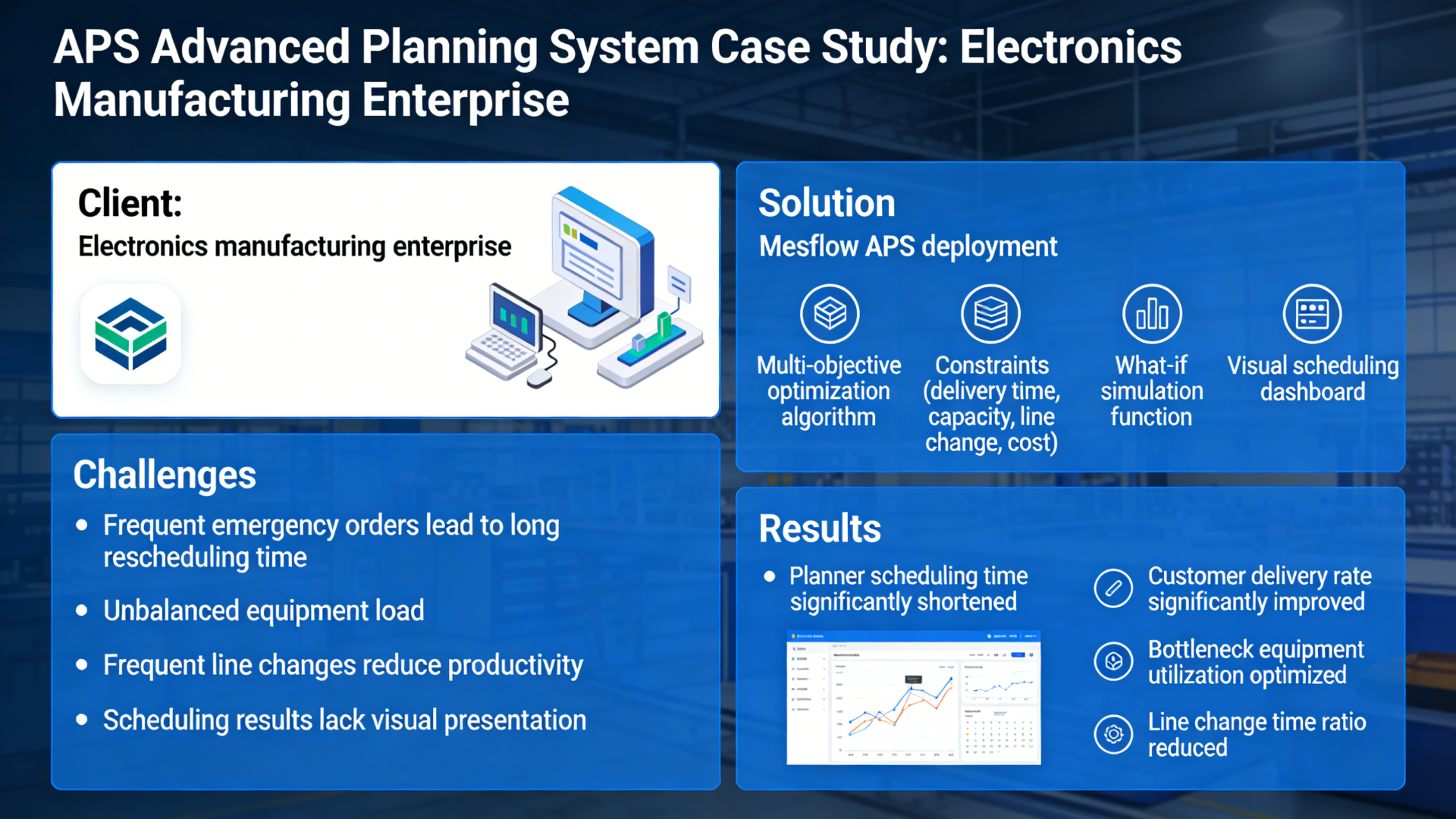

APS Advanced Planning System

Client: Electronics manufacturing enterprise

Challenge: When emergency orders are frequent, rescheduling takes a long time; equipment load is unbalanced; frequent line changes affect productivity; scheduling results cannot be visually presented.

Solution: Mesflow deployed an APS advanced planning and scheduling system for the client, adopting multi-objective optimization algorithms to achieve intelligent scheduling. The system comprehensively considers multiple constraints such as delivery time, capacity, line change, cost, etc., automatically generates optimal scheduling plans; develops 'what-if' simulation function to support quick assessment of order insertion impact; realizes intuitive display and dynamic adjustment of scheduling results through visual scheduling dashboard.

Results: Planner scheduling time significantly shortened; customer delivery rate significantly improved; bottleneck equipment utilization optimized; line change time ratio reduced.

Quality Management System

Client: High-strength fastener enterprise

Challenge: Quality data is recorded on paper work orders and Excel, querying traceability records takes a long time; process quality monitoring lags; SPC relies on manual calculation; quality data cannot be connected with supplier data.

Solution: Mesflow built a full-chain quality management system covering 'raw materials - production process - finished product inspection - after-sales traceability' for the client. Deployed production line data collection terminals to realize automatic collection and real-time upload of key quality data; built quality data warehouse, established traceability system with three-code association of batch number, serial number, and product number; deployed SPC module to realize real-time monitoring and abnormal early warning of process capability of key processes.

Results: Quality traceability time significantly shortened; batch quality accidents significantly reduced; process defect rate reduced; SPC abnormal early warning response time shortened.

Energy Management System

Client: Chemical production enterprise

Challenge: Energy consumption data collection relies on manual meter reading, unable to support refined analysis; energy consumption cannot be associated with production batches, unable to accurately calculate product unit consumption; lack of carbon emission accounting capability; energy consumption anomalies difficult to locate.

Solution: Mesflow deployed an Energy Management System (EMS) for the client, building a complete energy management closed loop of 'collection - monitoring - analysis - optimization'. Adopted multi-source data collection architecture to realize automatic collection of all energy media such as water, electricity, steam, etc.; built energy data model, accurately associating energy consumption data with production batches and product models; developed carbon footprint accounting module to automatically calculate carbon emissions of each product; deployed energy consumption anomaly early warning function to realize timely discovery and rapid response of energy use anomalies.

Results: Comprehensive energy consumption intensity decreased; product unit consumption accounting accuracy improved; carbon emission accounting efficiency increased; energy consumption anomaly discovery time shortened.